TECHNOLOGY

Becue was born with the specific purpose of putting technology at the service of billiards. Research and development are the pillars on which Becue is founded.

We are specialists in materials, carbon and composite fibers in particular

These “fabrics”, wisely used, allow us to develop infinite combinations, all aimed at the same purpose: to innovate.

- Offering the customer the best product on the market in terms of performance and feel

- Combining technical solutions with a unique and refined design

- Constantly pursuing research and development for our products. For this reason, our philosophy is to view each new product as an excellent starting point for the next

Becue is the world's first company to offer not only carbon fiber shafts, but also butts, thanks to years of extensive research and development. This innovation has paved the way for the introduction of the groundbreaking LEONARDO BALANCE SYSTEM.

INNOVATION

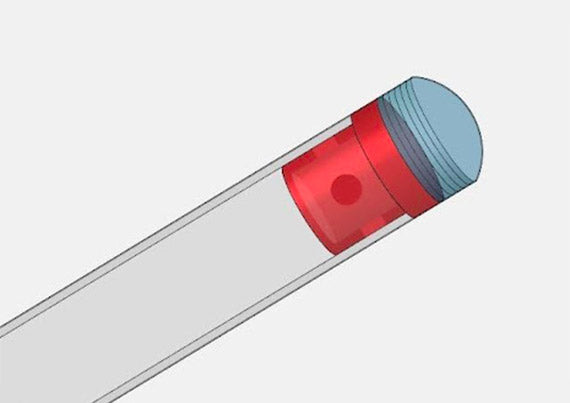

Aurora front end technology

High performance

The AURORA system, integrated with our tips, is therefore the fundamental component that guarantees a very low deflection in all game situations, regardless of the stroke power. And this is the real innovation: Providing the end user with a tool that maintains its mechanical and performance characteristics almost unchanged, regardless of the type of shot.

Carbon fiber cue butt

LBS - Leonardo Balance System by Becue

Each object conceived and made in Becue must reflect the company's philosophy, that is innovate without losing sight of practicality and design. The new Leonardo Balance System perfectly combines all these characteristics. Our balancing system was born with the specific purpose of being:

- Quick

- Intuitive

- Easy to use

- Easily transportable

- Usable in any situation

It often happens that overnight a player finds himself needing to change the weight of his cue in order to adapt himself and his cue to the cloth or balls, or the game he is playing at or simply because that day he need a different feeling with the cue.

Carbon Shafts, different models to adapt different needs and playing styles

Becue is a company specialized in the processing of carbon and composite fibers applied to billiards. Our goal, therefore, was not and is not to create just an extraordinary carbon shaft for our players, but to put them in the ideal conditions to try a unique experience with a carbon total equipment.

In fact, our play shafts are not one the evolution of another, but each one represents a different game option. They have different characteristics from each other to adapt to different gaming needs and player needs. Becue does not offer a single shaft that will satisfy the needs of every player, this will be impossible. Becue is proud to offer a multitude of shafts and carbon products, able to adapt and match the needs of the individual player, who can evaluate and choose them consciously based on their skills and expectations of the game.

Becue know-how

This is why Becue is the only company in the world that thanks to its know-how is able to provide its customers with a catalog of shafts and carbon products with different mechanical characteristics, which are not limited to the simple tip diameter changing or the components used, but which arise from different laminations and internal structures, designed, tested and built to give the best response in the different phases of the game and, above all, to the different kind of players. This because not all players are the same.

Aerography, Not Only An Aesthetic Matter

Creating highly innovative and technological products is Becue's mission. Giving them a unique and inimitable design is in our DNA. The continuous search for harmony and simplicity of forms is the hallmark of our products. It represents the quality of made in Italy at first look. Carbon has enormous benefits from a performance point of view. In particular, Becue is the only company to offer not only play shafts but also its own enterely carbon fiber made butt.

Made by hand

From the point of view of the decorations applicable to it, it has limits, mainly linked to the need to keep unaltered the fibers of the raw material that composes the butts. Therefore, significant incisions, deep inlays and similar techniques, can seriously compromise the performance and the feeling with the product.

In addition to this fundamental aspect, however, there was our firm will to offer our customers something innovative and extraordinarily unique. Here, after a multitude of feasibility studies and practical attempts, we were able to identify the most suitable and performing solution in airbrushing.

The particular conical shape of the cues combined with the desiredchromatic effects do not allow the use of serial masking or mechanized work. Each individual airbrushed butt is therefore worked, by a decorative point of view, entirely by hand, in a meticulous and absolutely planned process in every phase.

All the airbrushes, from the cues on the website catalog to the custom ones, are made entirely by hand by a professional airbrush painter who boasts collaborations with the most important brands of Italian design. This has allowed us over the years to satisfy even the most demanding customers by creating real "challenges" of customization.

If you wish to submit your custom graphics, do not hesitate to send the request.

- Choosing a selection results in a full page refresh.